Lindquist Machine Corporation

Capabilities & Facilities

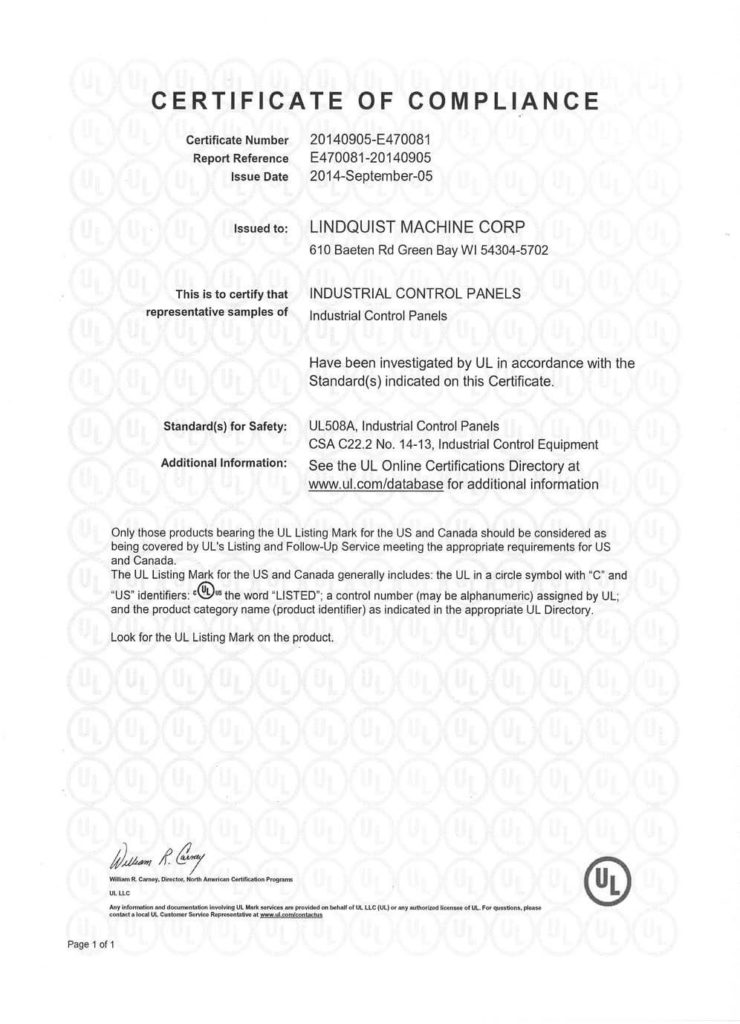

ISO 9001 : 2015 UL DQS Inc.

Certification Number: 10000400 QM15

Custom Machine Design / Build Applications

Build to Print Applications

Vertically integrated manufacturing capabilities

Come In For a Tour

Square Foot Manufacturing & Assembly Area

Square Foot Office Area

Capabilities & Equipment

- Assembly Bays

- Climate Controlled Assembly Bays

- CNC Machining Centers

- CNC Boring Bars

- Manual Boring Bars

- Grinders

- Paint Booth

- Fabricating Equipment

- Welding Certifications

- Quality Control Equipment

- Power & Air

- Certifications

Assembly Bays

- Total of 35,000 sq. ft. of assembly floor space

- 7 Overhead cranes – 5 to 25 ton (20 feet under hook)

- Forklifts – 11,000 lbs. capacity

Climate Controlled Assembly Bays

- 6,550 sq. ft. of temperature and humidity controlled assembly space; for confidentiality and security issues, this area can be arranged into 3 separate

assembly areas of 3,150 sq. ft., 2,500 sq. ft., and 900 sq. ft. - 3,000 sq. ft. of additional assembly floor space with 2 ton overhead crane

- Large door opening 14’ 10” Wide X 14’ 10” High

- Outside riggers available for heavier/wider loads

CNC Machining Centers

- (1) Hurco DCX31i Double Column Machining Center with WinMax 5 control.

Travels:

X=126”, Y=82.7”, Z=36.2”. Table size: 118.1” X 66.9”. 40 tool Automatic Tool

Changer. 10,000 RPM spindle, 80 HP. Through the spindle coolant, glass scales,

rotary table and tailstock (including 4th axis interface), conversational part and tool

probing, and enhanced DXF transfer - (1) Hurco VMX24 Vertical Machining Center with WinMax Dual Screen control.

Travels:

X=24”, Y=20”, Z=24”. Table size: 30” X 20”. 24 tool Automatic Tool Changer.

12,000 RPM spindle, 12 HP. Through the spindle coolant, rigid tapping,

conversational part and tool probing, and enhanced DXF transfer - (2) Hurco VMX42 Vertical Machining Center with WinMax Dual Screen control.

Travels:

X=42”, Y=24”, Z=24”. Table size: 50” X 24”. 24 tool Automatic Tool Changer.

12,000 RPM spindle, 24 HP. Through the spindle coolant, rigid tapping,

conversational part and tool probing, and enhanced DXF transfer - (1) Hurco VMX60 Vertical Machining Center with WinMax Dual Screen control. Travels:

X=60”, Y=30”, Z=24”. Table size: 66” X 30”. 30 tool Automatic Tool Changer.

8,000 RPM spindle, 30 HP. Through the spindle coolant, rigid tapping,

conversational part and tool probing, and enhanced DXF transfer - (1) OKK Model HM500S Horizontal Machining Center with Fanuc 310iS control.

Travels: X=24.8”, Y=24.4”, Z=27.95”. Table size: 19.7” x 19.7”, 990lbs capacity. Magazine capacity = 60. 30/25 H.P. Through the spindle coolant if using both pallets X is 24” per part. - (1) SuperMax 3 Vertical Machining Center with 15 HP two speed gear head. Travels: X=40”, Y=17.3”, Z=24.8”

- (1) OKK MCV Model 520’s Vertical Machining Center with full 4th axis.

Travels: X=40”, Y=20”, Z=20” - (1) OKK MCV Model 650’s Vertical Machining Center with full 4th axis.

Travels: X=50”, Y=25.6”, Z=25.6” - (1) Leblond Makino AMC 55 with Heidenhain controls.

Travels: X=21.65”, Y=12.59”,

Z=13.8” - (1) Mazak Model Power Master N: 60 HP 100” bed, swing = 34”.Swing over crosstie=22”

- (1) Samsung SL-MC/1000 CNC turning center with live tooling and bar feeder. 10” chuck. 25.6” swing, 13.8” cutting diameter. 40” distance between centers, 3” through hole 3500 RPM

- (1) Mori-Seiki SL-25 with 10” chuck, 10” diameter, 18” Distance between centers, 2.6 diameter through hole

- (1) Dainichi F35-1250 CNC Lathe 15” chuck, 15” diameter, 2500 RPM, 40” Distance between centers, 3.5 diameter through hole

CNC Boring Bars

- (1) MAG Giddings & Lewis FT 3500 Floor Type Traveling Column Horizontal Boring Mill with Siemens Sinumeric 849D CNC control.

Features of this machine are: 78” X 98” rotary table with 78” travel and 88,000 lbs load capacity (floor plate for remaining X travel); Through spindle coolant; CH-8 Head attachment for programmable contouring of bores; Part probing w/radio transmission; 60 position tool changer; Rigid tapping; 74 HP

Travels: X=394”, Y=122”, Z= 49”, W=78” - (1) Toshiba BTD-11 Table Type Horizontal Boring Machine (Remanufactured 2007) with Fagor 8055/ BM control and rotary table. Rigid Tapping. 20 HP

Travels: X=70”, Y=59”, Z=56”.

Table size: 55” x 63”.

Maximum table load: 13,860# - NEW DECEMBER 2022!! (1) Doosan DBC 130II Table Type Horizontal Boring Machine with Fanuc 31i control, rotary table, and full rotary B-Axis. Through spindle coolant, part probing, 90 position ATC and rigid tapping. 60 HP

Travels: X=118”, Y= 78”, Z= 63” Table size: 63″x70″; 33,000#

Manual Boring Bars

- (2) Nomura Model B-100-WP Horizontal Boring Bars with (3) axis readout. 20 HP

Travels: X=96”, Y=72”, Z=26”, W=41”.

Table size: 48” x 96”.

Max table weight: 13,200# - (1) Nomura Model B-100-SR Horizontal Boring Bar with motorized rotary table and (3) axis readout. 20 HP Travels: X=50”, Y=50”, Z=26”, W=43”

Table size: 45” x 50”

Max table weight: 11,000# - (1) Toshiba Model Horizontal Boring Bar with (3) axis readout. 25 HP Travels: X=118”, Y=83”, Z=63”, W=35”

Table size: 60” x 118”

Grinders

- (1) Kellenberger. Max diameter = 15”. Distance between centers = 37.5”

- (1) Okamoto Surface Grinder. 16” x 32

Paint Booth

- (1) Binks Paint Spray booth 14’ x 14’ x 24’ deep

Fabricating Equipment

- (1) Flow Flying Bridge CNC Waterjet. 50hp Single head, 6’ X 12’ table can cut through 6” material

- (1) Accushear 850012 Hydraulic Power Shear Model 8200012. ½”X12’

- (1) Promecam RG-154 160 Ton Hydraulic Press Brake. ¼” X 12’ w/automec CNC back-gauge

- (1) Geka Puma 55 Ton Ironworker Press

- (1) Wysong 10’ Power Slip Rolls

- (1) Aronson Model 160 16,000 lb Weld Positioner with power tilt and rotation and 54”

table. - (3) Weldsale Acorn Weld Tables 5’ X 8’

- (2) Miller Swing Arm Boom Welders with 15’ reach

- (8) TIG Welders

- (10) MIG Welders

- (2) Plasma Cutters

- (2) Stud Welders

- (1) Spot Welder

Welding Certifications

All LMC welding personnel are certified to the following industry specifications:

- AWS D 1.1 (structural steel)

- AWS D 1.6 (stainless steel)

- AWS D 1.2 (aluminum)

- GMAW (MIG) – carbon steel, stainless steel, and aluminum

- GTAW (TIG) – carbon steel, stainless steel, and aluminum

- FCAW (Flux-Core) – steel and stainless steel

- Nuclear: QL-2/QL-4

- In-house Level 1 Certified Weld Inspector (visual and non-destructive)

Individual welding qualifications are available by request. If a qualification is required that is not listed here LMC will become qualified in that particular specification.

Quality Control Equipment

- (1) LKG90C Large Bridge Style Coordinate Measuring Machine, running PC DMIS software. Travels: X=120”, Y=60”, Z=40”.

- (1) Mitutoyo Model B715 Coordinate Measuring Machine with IBM microprocessor running QCT Inspect 3D Pro Software. Travels: X=28”, Y=60”, Z=24”

- (2) Surtronic/Taylor Hobsen Profilometer

- (1) Surtronic 3+ Digital Profilometer (computer accessible)

- (8) Granite Inspection Tables

- (3) Digi-Height Verniers

Full complement of dial indicators, parallels, gauge blocks, dial bore gauges, ring & pin gauges, sine bar, etc.

Power & Air

(1) Planer Mill, 38” x 140” Table with 42” x 42” opening

Main assembly building power:

400 amp 480V 3 phase bus duct

400 amp 480V 3 phase test switch

200 amp 3 phase 60 amp receptacles

Main assembly air supply:

1 ¼” line @ 110 psi from 50 HP rotary screw compressor

Other power or air supplied by generator/standby compressor

Certifications

Industries We Serve

“The factory automation solution that Lindquist Machine provided us was on-time, easy to install, achieved our project ROI, and offered us a competitive advantage in our marketplace. Lindquist Machine is our first choice for factory automation investments and I would highly recommend them to other end-users.”

President/CEO

Amerilux International

President/CEO

Amerilux International